Groundbreaking Automation Project Continues for top Mold Maker

Published Mar 28, 2024 | Posted in Manufacturing, News, Technology

Founded in 1975, Cavalier Tool & Manufacturing Ltd. of Windsor, Ontario, produces more than 160 medium-to-large-size injection and compression molds per year with a team of 200 in three facilities in the Windsor area and three additional facilities in India, that provide design, purchasing, estimating and accounting services. The company not only designs and builds molds but also conducts feasibility studies, designs parts, makes mold modifications/repairs, and offers tryouts and small production runs for customers in the ground transportation (automotive, commercial truck, agricultural equipment, recreational vehicle), industrial (materials handling, fluid handling) and medical markets. To ensure it remains globally competitive now and in the future, Cavalier has partnered with Hermle AG and made a decade long commitment to increase automation.

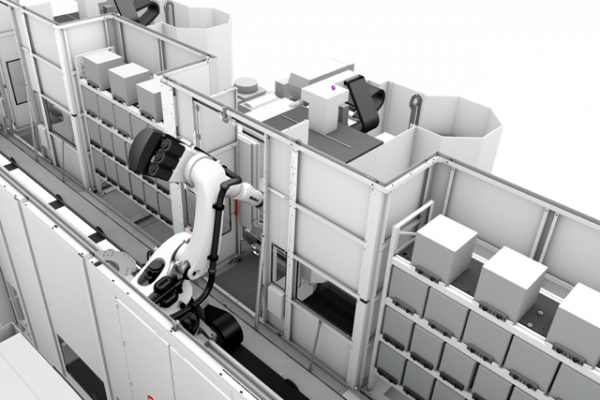

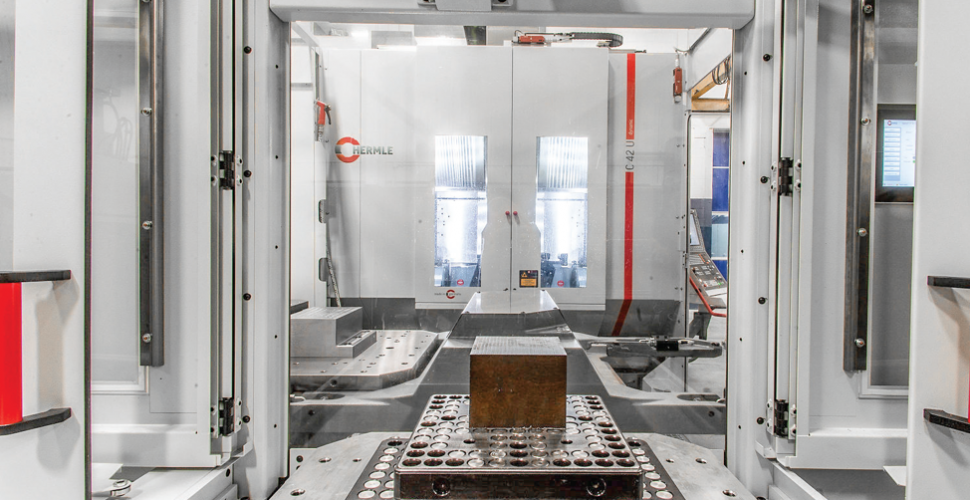

Shown here is the first automation unit Cavalier installed with a Hermle C42 U five-axis CNC and five Hermle PW850 pallets, plus a two-axis pallet changer/shuttle.

This multi-station system enabled the team to cut faster, reduce setups and shorten time between the end of one job and the start of the next. This manufacturing cell is still in operation.

Image courtesy of Cavalier Tool & Manufacturing Ltd.

Paradigm Shift Affects Product Mix, Investments

Recently, the types and quantity of molds Cavalier produces have shifted, owing to several trends. While it actually produced fewer molds in 2023— down from over 200 two years ago— the molds the company now builds are larger and more complex thanks to significant growth in the heavy truck segment. During Q4 2023, the company produced not one but two $1 million tools.

Rapid growth in the truck segment, whose parts tend to be very large, has also meant that Cavalier is producing more compression molds these days.

Additionally, since the pandemic, Cavalier has reshored complex tool components it used to produce in China.

Principally, this was done to address supply shortages and shipping delays that plagued most of the industry during 2020-2022. However, that meant a larger portion of its tools was being produced in a country with high labor costs and an industry requiring high capital investments. To remain globally competitive today and tomorrow, Cavalier management took a hard look at ways to drive down its cost of goods sold (COGS).

They concluded that the best way to do this was to increase automation. “This is really a matter of our survival — not just now but into the future,” Doug Brockman, Cavalier General Manager, explains. “We tell our people that if we don’t make this investment in automation, they won’t have a job in 10 years because the only way to stay competitive in a global market is to invest in sophisticated equipment and to automate.

To remain successful, we can’t afford to do things manually.”

Cavalier management and shop leaders worked together to develop an ambitious, multiphase program to increase automation and manufacturing efficiency and set distinct goals at each level. The company already had a good working relationship with CNC machinery OEM Hermle AG, who agreed to work closely with the mold maker to design and outfit manufacturing cells to meet the company’s needs. Since Cavalier also had significant investments in workpiece holding systems from Erowa Ltd., used for smaller workpieces, and FCS System Srl., used for larger workpieces, they wanted to incorporate them in the new manufacturing cells.

Before moving to a new phase of implementation, the team agreed to assess how equipment ran and review best practices and lessons learned to determine what, if anything, to change before setting new goals and beginning the next phase of automation.

Phase 1: 2014-2015

At the start of Phase 1 of its automation program, the Cavalier team had three goals: cut faster, reduce setups and reduce chip-to-chip time (defined as the time between the end of one job and the start of the next on the same machine).

The first two goals were addressed by purchasing a Hermle C42 U five-axis CNC machine — Cavalier’s first five-axis mill for steel — which was selected for its stability and accuracy while running at high spindle speeds, and its ability to drill and both rough and finish mill. This meant that all work except EDM could be performed without moving a workpiece, thereby reducing setup steps and time.

The third objective was addressed by purchasing five Hermle PW850 pallets and a pallet changer/shuttle that loaded/unloaded pallets from the CNC. At any given time, up to four pallets loaded with workpieces were in the manufacturing cell: one in the CNC being machined, two to the side in ready stations and a fourth in the robot’s second arm. As soon as one job finished, the shuttle removed it and loaded the next from the ready station. Since multiple jobs (and programming) were preloaded into the manufacturing cell ahead of time, downtime between jobs was reduced. If problems arose while in the CNC, the job was terminated, the pallet/workpiece removed, and another loaded into the machine, enabling more unattended run time.

The proprietary Hermle pallets were what the pallet shuttle was designed to pick up/move, and the CNC was designed to accept them. The team’s workaround was to mount either a 500 × 500-millimeter/20 × 20-inch FCS pallet on top of each Hermle pallet or a set of Erowa 148 chucks and collets, which enabled them to have multiple stations ready to machine workpieces held by Cavalier’s preferred work holding systems. After machining, it eliminated the need to depalletize workpieces and then repalletize them before moving to EDM. However, if the Hermle pallet coming off the CNC was loaded with an FCS pallet and the team needed to mount a smaller workpiece held by an Erowa system, then they either had to disassemble the FCS system and reassemble the Erowa before loading the workpiece, or they had to sequence jobs in such a way as to fit on whatever pallet was available next.

At the end of Phase 1, the team evaluated approaches they’d tried and how well each had worked. They found that the high-speed, five-axis Hermle CNC cut faster and more accurately and reduced setups. They also found that the multi-palleted workholding system shortened setups and contributed to faster removal and transport to the next machine.

By developing and inventorying a library of presized round and square steel blanks in common sizes, machining steps and time were reduced. The workholding solution permitted 5-1/2-sided finish machining of all features (including engraving, vent channels and molding surfaces) on all sides of the blank except where the stub of excess material was attached.

Photo Credit: Cavalier Tool & Manufacturing Ltd.

An interesting experiment the team tried during Phase 1 was creating a library of preconfigured steel blanks in common shapes and sizes to produce smaller inserts. Square and round blanks were produced by the prep department, where steel was saw cut, the ends were skimmed, and mounting holes were drilled and tapped before being sent to the appropriate machine/cell for mounting and machining. Rather than start the next job by squaring, skimming and drilling holding holes into a block of steel, the preconfigured blanks were ready to go. With prep work eliminated, cutting could begin once the blank was loaded in the CNC, saving time. Any leftover material on the bottom face was simply removed via wire EDM after machining.

“When we looked at the cost of steel — about $2.00/pound — and we looked at the cost of running our CNC, we realized that with preconfigured blanks, we could start cutting within 5 minutes rather than spending 2 hours of machine time prepping the block before we started cutting,” Rob Wilson, Cavalier Maintenance Manager, explains. “Clearly, the cost of throwing away some steel versus prep, setup and machining time made this one of our better ideas.”

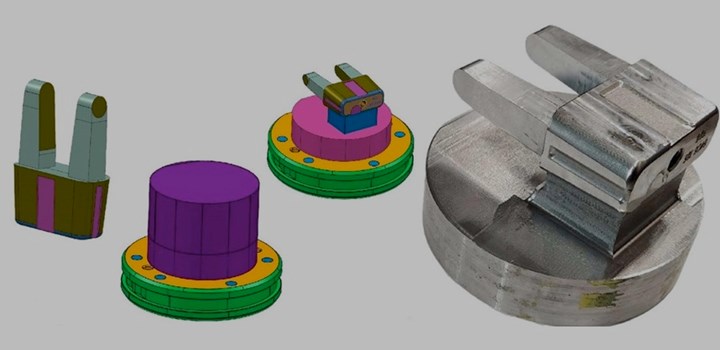

Another experiment turned best practice was that after a workpiece was removed from the CNC and moved to a wire EDM to be removed from the stub of remaining material, the team realized that as the workpiece was cut off, it fell into the water bath, requiring team members to fish around in the tank to retrieve it. Meanwhile, the base that was removed sat in the holder.

The team solved this with two approaches. First, they experimented with sets of magnets until they developed a configuration that prevented the workpiece from falling into the tank. Second, during the EDM process, they left a small tab of the stub attached to the workpiece that could easily be snapped off after removal from the EDM. While this tab didn’t affect final part functionality, it did facilitate removal from the stub. Although each change represented small gains in time, taken together, they added up to bigger savings in man-hours and handling.

“We had a stellar team working on ways to make our processes more efficient and they spent a lot of time asking ‘What if’ questions about every aspect of the manufacturing environment,” adds Brockman. “In the end, it’s not enough to buy the latest technology; it’s what you do with that technology that makes all the difference.”

Phase 2: 2017-2019

Despite the many successes of the Phase 1 manufacturing cell, the team recognized that five pallets were insufficient for Cavalier’s needs. As Phase 2 began, their goals were to run more unattended hours, improve their workholding solutions and increase component throughput.

These goals were addressed by significantly expanding the workholding stations by installing a Hermle Pallet Flex System with a multilevel library holding 18 pallets/workpieces. This, in turn, was serviced by a four-axis pallet changer/shuttle, which moved on both linear and rotary tracks to feed another five-axis Hermle C42 U CNC positioned beside the library. As before, the team mounted either FCS pallets or Erowa chucks/collets on the Hermle pallets and dealt with the limitations.

“At Cavalier, our DNA is ‘Let’s try stuff,’ so during this phase of automation, we tried lots of funky ways to improve workholding, such as using V blocks and three chucks to hold our workpieces — things that didn’t work out — and we also found a new way to make lifter rods that, while cool, wasn’t cost-effective,” Wilson recalls. “Because we weren’t afraid to fail, and this was a more flexible system than we had in Phase 1, we felt free to use out-of-the-box thinking. A lot of the things we tried turned out to not be such great ideas.”

Toward the end of Phase 2, the team reviewed successes and failures.

They agreed it was advantageous to have two identical CNC machines in both Phase 1 and 2 manufacturing cells that used common programming and resources (including tools) because it gave the team scheduling flexibility so a pending job could run in whichever machine/cell was open. However, there was growing frustration with the high cost of the workholding workaround, which the team wanted to address going into Phase 3.

As previously noted, the pallet shuttle and CNC were designed to accept the proprietary pallets, which required the workaround of installing FCS pallets or Erowa chucks/collets on top of the Hermle pallets. This pallet stacking added Z-axis height that, while workable given the large machining envelope of the C42 CNCs, would be limiting in the smaller CNCs being considered for Phase 3. It also added considerable cost because the Erowa collets couldn’t be used alone and required a full set of chucks and collets, a combination that ended up costing $8,000/pallet. Given the much larger manufacturing cell planned for Phase 3, with three CNCs and a greatly expanded pallet library to feed them, the high cost of continuing with the workaround meant more innovation was needed. Hermle came back with a clever solution to the workholding headaches.

Phase 3: 2023

Going into Phase 3 planning, goals were to maximize unattended machining, further increase capacity to accommodate anticipated growth and resolve workholding issues. As Cavalier collaborated with the team at Hermle, several significant changes were made.

First, monitoring had shown that 90% of what had been cut in Phase 1 and 2 manufacturing cells were smaller components that had previously been offshored. Hence, the decision was made to install three five-axis Hermle C32 mills rather than the larger C42s.

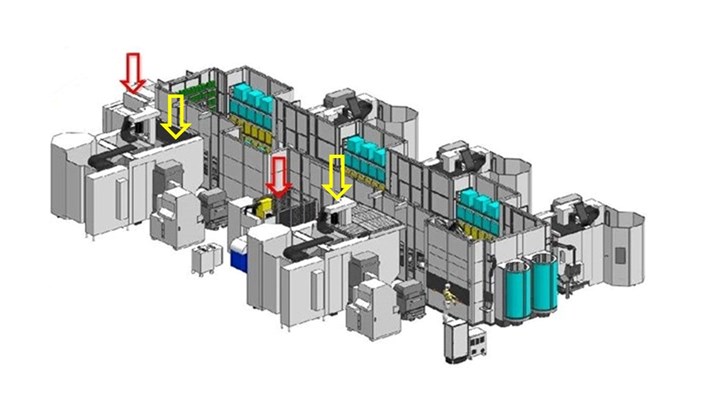

Second, to maximize throughput and unattended machining, Hermle developed a fully enclosed, 231-position, multilevel library that was managed by a seven-axis KUKA robot (from KUKA Robotics Corp.) moving along a 20-meter/65-foot track to retrieve palletized workpieces and feed the three CNCs. This time, the entire cell — robot and CNCs — was controlled by Soflex software (from Soflex Fertigungssteuerungs-GmbH).

To address longstanding workholding issues, the storage system, robot and CNCs were designed to accept a variety of pallets using the same handling attachment. To ensure the Erowa chucks/collets could be used in this situation, a series of three custom mounting plates the same size as the smaller FCS plates (but without extensive mounting holes) were used to mount Erowa 148 chucks. The library’s storage bins were configured to hold 77 FCS pallets (45 that are 400 Å~ 400 millimeters and 32 that are 500 Å~ 500 millimeters). It was also configured to hold 151 Erowa 148 collets that can be changed in and out of the three custom Erowa mounting pallets as needed.

This system represented the highest level of automation and flexibility Cavalier has yet used. Unsurprisingly, as they continued delving deeper into automation, the team found new things that needed to be addressed.

“With our CNCs running unattended more, we learned we needed to probe every blank at the start of the cycle to ensure there was enough excess stock to cut the component cleanly, but not too much or the machine would crash,” Wilson explains.

“We worked with Hermle, our CAM software and controller providers, and put all the pieces together to create a probing software routine that checks that the raw block has no more than 0.60 inch [15 millimeters] and no less than 0.02 inch [0.50 millimeter] of excess stock before machining starts. When we had humans watching the machines, we relied on them to catch a problem like this, but as automation increased, we found a previously unknown variable we had to optimize around.”

To date, the Phase 3 setup has met Cavalier’s goals for further process improvements, with all machines running unattended.

Now, the challenge is to find enough additional work to ensure the manufacturing cell is used to full capacity. COGS have also come down enough that Cavalier can produce complex small components cost-competitively with offshore resources, thereby enabling the company to repatriate 100% of its complex 3D components.

The company continues to seek ways to drive cycle time down and is currently evaluating other revenue streams to keep the machines busy besides producing mold components.

Phase 4: 2024 and Beyond

When economics support further expansion, the company plans to add more machines to Phase 3’s manufacturing cell. These include one wire and one sinker EDM, which will reduce workpiece handling and enable more process steps to be completed inside the cell. Cavalier also plans to add two larger five-axis Hermle C52 CNCs, which will be capable of holding the larger 500 × 500-millimeter pallets already included in the current library racking system.

“We never do the same job twice, so as we add automation, we continuously have to adapt our technology for a high mix/low volume environment,” Brockman adds. “From our first multi-palleted manufacturing cell, we learned a lot that we used to improve productivity as we added more pallets in our second cell. However, we were still using a lot of manned hours. We used what we learned there to design our third cell, which has given us even more unmanned hours and continues to teach us there are still things we need to innovate around.”

In Phase 4, the team’s goals will be to add one sinker and one wire EDM (red arrows) and two five-axis Hermle C52 CNCs (yellow arrows) capable of cutting workpieces on the larger FCS pallets. Photo Credit: Hermle AG

“One thing we’ve noted as our tools have gotten bigger and we’ve added more automation is that we use fewer people to produce each tool — which is an advantage at a time of global skilled labor shortages and record baby boomer retirements,” notes Tim Galbraith, former Cavalier general manager, who himself became a retiree in 2024. “However, adding automation doesn’t necessarily mean we need fewer people. We still need skilled workers. In fact, as we look to the future, we need people with even more skills who are trained for jobs that don’t even exist yet.”

Full article here: MMT324 Cavalier Tool

By Peggy Malnati, MMT

FOR MORE INFORMATION

Cavalier Tool & Manufacturing Ltd.

info@cavaliertool.com / cavaliertool.com

Doug Brockman, General Manager

Hermle / info@hermleusa.net / hermleusa.net

Erowa / info.usa@erowa.com / erowa.com

FCS / info@fcssystem.com / fcssystem.com

KUKA Robotics / kukainfo@kukarobotics.com / kuka.com

Reprinted from the March 2024 MOLDMAKING TECHNOLOGY Magazine and Copyright © 2024

by Gardner Business Media, Inc., 6915 Valley Avenue, Cincinnati, Ohio 45244-3029.