How Quality Molds Drive Success: A Guide for Consumer Goods Professionals

Published Nov 30, 2024 | Posted in Manufacturing, Technology

In today’s competitive consumer goods industry, efficient and reliable manufacturing processes are key to delivering high-quality products that meet market demands. One cornerstone of success in this market is mold making for plastics. This blog explores the vital role mold making plays in consumer goods production and how partnering with a skilled mold shop can elevate product quality and operational success.

What is Mold Making for Plastics?

Mold making for plastics is the process of designing and manufacturing molds used in plastic molding. A mold is a tool used to shape materials into a customer’s desired part or product. The mold is a critical component of any production process. Cavalier Tool specializes in building medium to large tooling for diverse applications.

For Tooling Engineers, the importance of precision in mold making cannot be overstated. High-quality molds ensure:

Accuracy: Every part maintains consistent part geometry

Efficiency: Faster cycle times and reduced scrap improve overall output.

Durability: Robust molds capable of handling continuous use reduce maintenance needs and downtime.

Plastics in the Consumer Goods Sector

Mold making for plastics supports a wide range of applications within the consumer goods sector. Some examples include:

- Storage Bins

- Containers

- Sporting Goods

- Kitchen Tools

- Smartphone Cases

- Tackle Boxes

- Coolers

- And Many More.

Plastic Consumer Goods can be made with a variety of mold types. At Cavalier Tool and Manufacturing Ltd. we build Plastic Injection Molds, Aluminum Molds, Gas Counter Pressure Molds, Compression Molds, Injection Compression Molds, Multishot Molds, Structural Foam Molds, and Stack Molds. Click Here to learn more about the different mold types.

Key Considerations in Mold Making for Plastics

To maximize the efficiency and effectiveness of mold making, several factors must be considered:

Material Selection

Choosing the right material for the mold is critical. Steel and aluminum are common choices, each offering specific benefits depending on production volume and the specific needs of your part.

- Steel

- There are many different types and grades of Steel.

- Steel is the most common material in mold making for plastics.

- Steel is often chosen for its durability. The enhanced durability of specialized tool steels can lower cost per part over an extended production run.

- Aluminum

- Aluminum is lighter than steel, this makes it ideal for extraordinarily large tooling projects.

- Aluminum isn’t as hard as steel, as a result it can be machined at a faster rate. This ultimately leads to a lower total cost for the customer.

- A significant portion of cycle time is a result of the time it takes to cool a plastic part. A particular advantage of aluminum is its higher rate of thermal conductivity.

Precision in Design

A skilled mold shop employs a combination of advanced technology, expertise, and rigorous processes to ensure that each mold meets exact specifications. Prior to your order Cavalier Tool’s Design for Manufacturing (DFM) team will ensure the feasibility of your part to provide moldability, production efficiency, optimal cycle time and a cost-effective tool design.

Cooling Design

Efficient cooling, such as conformal cooling channels, reduce cycle times and enhance mold longevity. These designs minimize warping and improve product quality.

Maintenance and Durability

A well-made mold reduces maintenance needs, but regular upkeep ensures consistent performance over its lifespan, supporting long-term production goals.

Why Quality Mold Making Matters for Consumer Goods

The quality of the mold directly affects production efficiency, product consistency, and overall costs. Here’s why investing in superior mold making for plastics is essential:

Reduced Downtime

High-quality molds are more durable and less likely to require frequent repairs, ensuring smooth production schedules.

Enhanced Product Quality

Precision molds ensure every product meets dimensional and functional requirements.

Lower Total Cost of Ownership

While premium molds may require a larger upfront investment, their reliability and longevity result in significant cost savings over time.

Automation and Innovations in Mold Making

Advances in automation have transformed mold making for plastics, enabling faster, more precise production. Here are some of the innovations you should know about:

Robotics

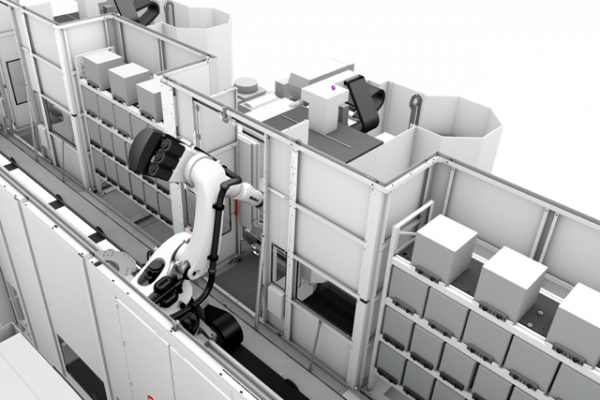

Robotics are increasingly being used in mold shops to enhance productivity and consistency. Windsor, Ontario based tool manufacturer Cavalier Tool partnered with Hermle AG to produce a fully automated work cell at their third plant to reduce setups, machine faster, promote unattended machining, and increase throughput. The work cell features a seven-axis Kuka robot that will ultimately manage seven different machines and produce a range of components for Cavalier Molds.

Increased CAD/CAM Integration

Modern software allows seamless transitions from design to machining, reducing errors and improving efficiency.

Five-Axis CNC Machining

This technology produces complex mold geometries with unparalleled precision, minimizing lead times.

Automated Quality Control

Tools like On-Machine Verification Probes ensure molds meet exact specifications, reducing production issues.

Real-Time Monitoring

Internet of Things enabled systems track machine performance and predict maintenance needs, minimizing downtime.

By leveraging these innovations, mold shops deliver high-performance molds that exceed expectations in consumer goods applications.

Partnering with a Skilled Mold Shop for Plastics

Selecting the right mold shop is critical for success in mold making for plastics. Experienced mold makers understand the nuances of tooling for consumer goods and are equipped to deliver precision and efficiency. When choosing a mold shop, consider:

Experience in Your Industry

Look for mold makers with a proven track record in consumer goods applications.

Advanced Technology

Shops utilizing the latest automation and machining tools can handle complex designs with speed and accuracy. At Cavalier Tool our machining centers and processes are custom built to maximize value for our customers.

Commitment to Quality

A strong quality assurance process ensures molds meet your exacting standards. Cavalier Tool in Windsor, Ontario is ISO 9001:2015 certified for Design and Manufacture of Plastic Injection, Compression, Structural Foam, Die Cast and Prototype Tooling for Various Industries.

Support Services

Maintenance, repair, and technical support are essential for maximizing mold lifespan and production uptime.

The Canadian Advantage in Mold Making for Plastics

For companies operating in North America, Canadian mold shops offer distinct benefits:

High Standards of Quality

Canadian manufacturers are well known for precision and reliability. Our motto at Cavalier Tool is “Understand what needs to be done, do it right the first time, and do it better tomorrow.”

Access to Skilled Workforce

Advanced training programs and government funded projects like Career Ready with CTMA ensure a highly skilled labor pool for mold-making expertise.

Proximity to Major Markets within The United States and Mexico

Located near the U.S. and Mexico Canadian shops offer fast turnaround times and easy communication.

Commitment to Sustainability

Many Canadian mold shops focus on energy-efficient and environmentally friendly manufacturing practices. A point of focus in 2024 is supporting plastics recycling initiatives.

Conclusion

For tooling engineers in the consumer plastics industry, partnering with a skilled mold shop is a critical step toward achieving manufacturing excellence. From high-quality molds to innovative automation techniques, investing in the right mold maker ensures precision, consistency, and long-term success.

If you’re ready to take your production capabilities to the next level, consider working with a mold shop that prioritizes People, Process, and Equipment. Consider The Cavalier Experience.

Contact us to learn how our mold-making services can support your consumer goods applications.