A big hit with VR, automation and a system beyond top mold building

Published May 28, 2024 | Posted in News, Technology

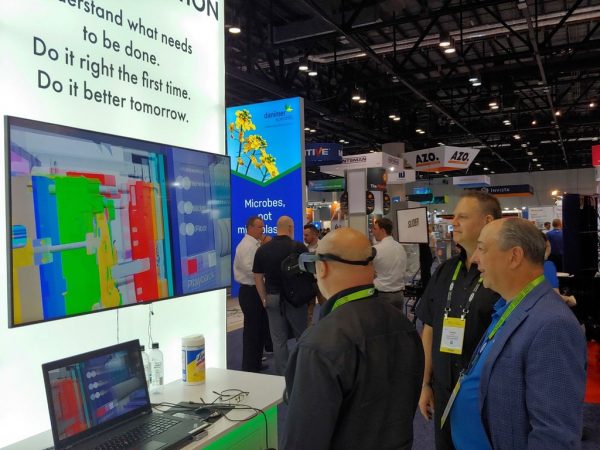

Imagine walking into a 10- ton mold and being part of the inner workings of the tool.

“That was a highlight and we were the first to do it,” says Jim Korenev, Cavalier Development and IT. “It was cool because it attracted a broad range of people.”

The virtual reality training program was indeed a big hit at NPE 2024, held in Orlando, Florida May 6-10, 2024.

Even Plastics Today called Cavalier’s VR setup: “The Coolest Thing We Saw at NPE on Day O ne” in this published article.

ne” in this published article.

The mold maker is calling the VR experience the “fourth pillar” of its presence at NPE this year, with automation, toolmaking, and its people cast as the other pillars. “We have a system that goes beyond building molds,” says Cavalier Sales Manager Peter Gossmann. “It starts with our design for manufacturing (DFM) team. Prospective customers can vet their part design to optimize conditions that produce the best possible mold.”

Everyone who put on the VR goggles enjoyed the experience of learning about how a mold is constructed and how it functions by literally walking right inside the mold.

- Seeing the lifters and slides move as the mold opens to eject the part

- Looking at the water lines from inside to understand the extensive cooling provided

- Observing the hot runner flow channels

- Watching the ejector pins as they move to eject the part

Team Cavalier with help from staff at Invest-WindsorEssex worked together to ensure the VR show would be a success.

“Failure was not an option. We knew we could turn the impossible into the possible, “ says Korenev. “ Cavalier always makes sure things are done right.”

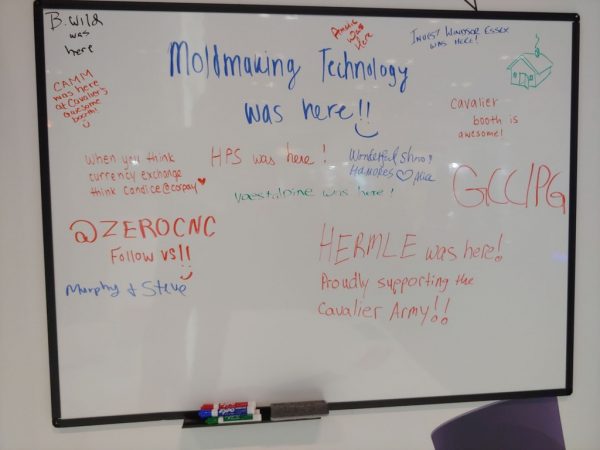

Christina Fuges, Editorial Director, MoldMaking Technology, knows Cavalier well and says it was great to see them at NPE showcasing their commitment to automation.

“I spoke with Peter Gossmann who explained that automation is helping to bring mold manufacturing back to North America, as the automated machining cells allow Cavalier to manufacture molds at less cost than overseas tooling. It also allows them to stay competitive, grow, take on more work and hire more people,” Fuges says.

“Peter also talked to me about their DFM (Design for Manufacturing) strategy that helps customers improve part designs, but more exciting than that was the virtual reality demo they had at the booth. I gave it a go and found it pretty easy to use and clearly saw the benefits to mold builders and their customers of using VR to educate and train inhouse staff as well as customer process techs about what is actually inside the mold and how it works. “

Fuges says in playback mode, she could see the mold running in the machine, see individual components of the mold and how they operate.

“And you can walk inside the mold to see the water lines and flow channels,” says Fuges. “Then in Explore mode you can actually grab components, rotate them around and even place them on a workbench. It’s fun and informative! “

Cavalier President Brian Bendig says Cavalier experienced a fantastic turnout at NPE and he credits planning before and during the show with their success. The VR pillar was very engaging and interactive and their videos at other pillars helped tell the story of The Cavalier Experience.

“And we had Team Cavalier on hand to answer questions and just connect with people who stopped by. “

The automation video was another hit since it showcased their use of robotics.

“People appreciated our level of automation – and how we provide automated solutions since it helps us get jobs done faster,” says Bendig. “ We’re heavily automated so we run all three shifts, even on holidays. Not all our competitors can do that because they don’t have the levels of automation that we have. People commented on how advanced we are and often said they were impressed with how we were so involved with technology.”

And by far: “Our goal is always to be your first choice for molds by providing you with the fastest cycles, the longest mold life with the least amount of maintenance.”

COLLABORATION A GAME CHANGER

Cavalier also collaborated with Invest WindsorEssex to bring the VR pillar to life – and to the market’s attention.

“This was a great engagement and this was many years in the making – with our VR CAVE and Cavalier, says Ed Dawson, Interim Executive Director, Automobility and Innovation Centre, Invest WindsorEssex

“The hard part was the simulation software that originally powered the VR CAVE wasn’t easily adaptable for some of the models that we were bringing in. A new partnership under our Ontario Vehicle Innovation Network grant funding, with a company called Virtualware, located in Hamilton, contributed to our success with this addition of a cross collaboration platform.

“It allows you now to use the VR headset like Cavalier did at the show,” says Dawson. “Virtualware created a custom VR CAVE player to allow the VR CAVE to be part of a realtime ecosystem including VR headsets. So if you were at a show you can have people collaborating and looking at projects or even training in real time.

This has been a real game changer for us.” Also a game changer for Cavalier.

“There is also potential to interact and engage with clients overseas to show projects potentially in real time, and it’s going to be more clearly understood when you’re using VR. Sometimes we call it mixed reality,” says Dawson.

“We were able to do the work for Cavalier with our time and with our software developer, Bryan Holmes. He did a lot of work to take Cavalier’s CAD model and bring it to life,” says Dawson.

“It has turned out to be one of the best projects that we’ve had for a couple of reasons. Obviously, they are our neighbors and it’s showing what’s possible using virtual reality. And we did this because with the new mobility sector, there are a lot of companies that are doing work in that space. But sometimes for confidentiality concerns, they are not always able to talk about it or celebrate it.”

Cavalier stepped in to celebrate it at NPE 2024.

“There’s been a lot of positive feedback from what we’ve seen,” says Dawson. “We’ve even had some groups of students we’ve shown it to as well as to Ontario Member of Provincial Parliament Andrew D owie who was also impressed with what he saw.”

owie who was also impressed with what he saw.”

Dowie says, “Cavalier is a fantastic local success story, and its use of advanced technologies keeps it at the forefront of manufacturing innovation.”

Dawson agrees. “Cavalier is innovative and a perfect candidate to work together on a project like this. They are perfectionists, and when we do something, we want to demonstrate that we can hit the level that Cavalier needs. And I think that’s what we’re excited about. It looked amazing. We were very happy,

“And Cavalier sharing this on social media is also a bonus. You have to sometimes shout about this from the treetops.”

Sales Account RepMark Perotti says he appreciates the role of technology at Cavalier since it sets them apart when it comes to delivering results for customers. “Many people brought up how they didn’t realize how technologically advanced Cavalier was. Representing a company like Cavalier helps us work with customers to achieve their goals.”

Sales Account Rep Jake Northrup says the show was huge and had much excitement surrounding it so it was a big plus to be able to meet with both current and future customers.

He says the show confirmed the health of the industry and there was much optimism, even during this election year. “I was able to get a read on things and everyone seemed optimistic and I was able to talk to people outside my normal network.

“Probably the key thing for me was the relationship building and networking with a lot of our current customers that were there and then the additional contacts from those companies. People would come by with other people in the organization from plant floor, quality and just different departments that I don’t normally interface with.”

We had our Cavalier team there as well that obviously aren’t with me when I go out to customer meetings so that was another benefit. Most of my big accounts were there and we spent a lot of time chatting and catching up with others in the booth and there were also some customer dinners,” says Northrup.

“And I also had some new prospects coming out of the show.”

He said the learning that comes from talking to such a diverse group of people is what made attendance at NPE so valuable.

QUALITY VISITS AT NPE 2024

Sales Manager Peter Gossmann says he initially expected the show to be jam packed after a six year hiatus but it was reasonably attended by industry people and less so by the general public.

“However, at our booth, we had as many as we would normally get in terms of visitors,” says Gossmann. “And the quality of the visitors was at a high level. “

Peter Gossmann

He says Cavalier was happy with the ROI on attending and also the feedback from visitors.

“I would say Cavalier is unique in that we benefit from trade shows,” says Gossmann. “Not everybody does it as well as we do.”

Both Gossmann and Bendig agreed supporting plastics was also a topic at the show – and it far extended beyond the politics of plastic bans as seen in Canada.

“Most people were talking about why plastics are so important,” says Bendig. “When you look at the medical field and food packaging, you know without plastics or single use plastics people would be a lot less protected from harmful bacteria and viruses.”

Gossmann says discussions around sustainability were very valuable. For example, Husky terms it this way: it is part of the circular economy. That is probably the best term you can use for plastics because it has the potential of being completely circular where nothing is wasted.”

Bendig says his team went to NPE to provide insight into the day-to-day concerns of plastic processor customers and to demonstrate how Cavalier works with them for mutually successful ongoing business.

As for feedback – Bendig says it might have been better to have the toolmakers grouped together as the show was indeed spread out. But overall the show proved worthwhile for Cavalier.

“We achieved our goal and we are grateful to get all the feedback from everyone who stopped by,” says Bendig.

“And now it is all about the follow-up from the show. Our work has just started as now we need to ensure we deliver on our promises. We say we are your first and best step to success so we always look ahead and we are always finding ways to get better, be better and do better.”

-30-